- WITTENSTEIN North America

- Products

- Galaxie® GH

Galaxie® GH

Galaxie GH® is a right-angle gearbox with hypoid input stage and adapter plate for mounting on standard industrial servo

motors.

- Your benefits

- Technical data

- Options

Galaxie® gearbox with hypoid pre stage and motor mounting adapter plate – additional planetary pre stage and hollow shaft.

.

Advantages

- Highest torque density

- Extreme torsional rigidity

- Completely maintenance free

- Improved synchronization accuracy

- Robust and precise output bearing

- Zero backlash

- Easy integration

Benefits

- Increased productivity

- More stable processes

- New, high performance machine generations

- Greater competitiveness

- Shorter project life times

| Galaxie® robustness line | |||||

|---|---|---|---|---|---|

| Size | Unit | 110 | 135 | 175 | 215 |

| Variant | GH | GH | GH | GH | |

| Outer diameter1 | D [mm] | 160 | 191 | 241 | 300 |

| Length2 | l [mm] | 215 | 260 | 302 | 381 |

Max. acceleration torque3 | T2B [Nm] | 1086 | 1800 | 4050 | 7500 |

| Max. output speed3 | n2max [rpm] | 95 | 80 | 61 | 50 |

| Nominal output torque3 @ n2N | T2N [Nm] | 450 | 750 | 1685 | 3130 |

| Nominal output speed3 @ T2N | n2N [rpm] | 23 | 20 | 15 | 12 |

| Emergency stop torque3 | T2Not [Nm] | 3000 | 5400 | 12000 | 22500 |

| Torsional rigidity3 | Ct21 [Nm/arcmin] | 370 | 650 | 1400 | 2700 |

| Ratio4 | i | 72-240 | |||

1 Without connectors/varies depending on mounting position

2 Without cooling connectors/varies depending on pre stage and motor dependent adapterplate

3 Values are subject to variations

4 Output turns to input

Technical data for reference only; specified values only valid with hollow shaft design/MF3 (with additional coaxial pre-stage) on request

Note

Optional hollow shaft may be possible on request. Ratio up to 2400:1 can be realized with additional planetary pre stage (no hollow shaft). Motor adapter plate and shaft coupling configurable for all common industrial motors.

Typical applications

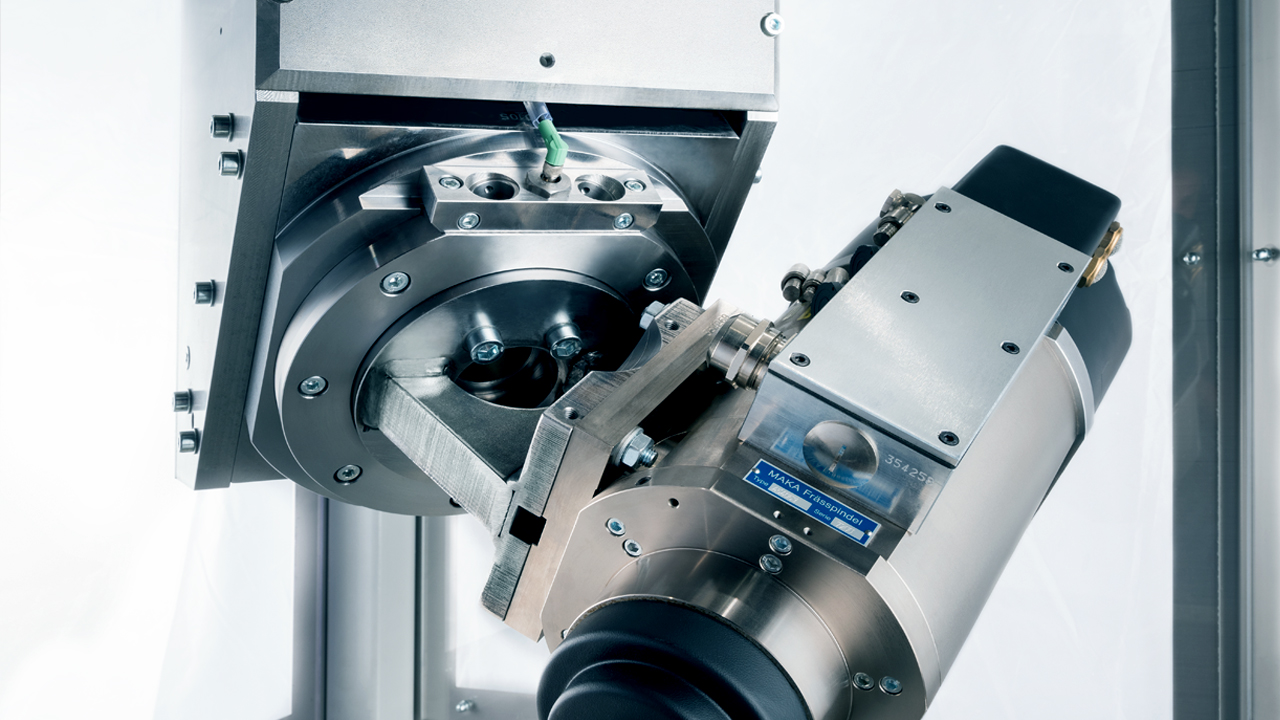

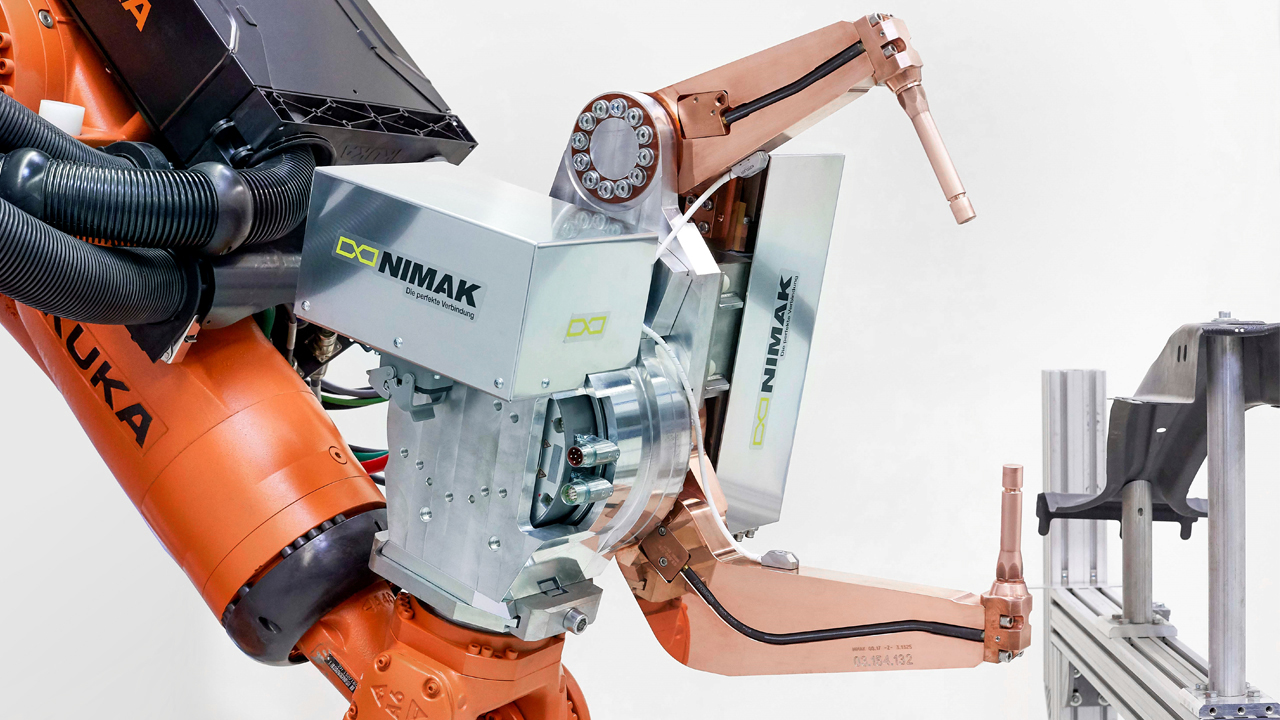

A/B/C Axis for precise positioning in CNC applications like milling and turning, Gantry end effectors and wafer handling.

Galaxie® GH

Kompatibel mit unterschiedlichen Servomotoren

(Siemens, Bosch, etc.)

Hohlwelle

(nur bei zweistufiger Ausführung)

Übersetzung

Zweistufig: 72 - 240 (Hohlwelle möglich)

Dreistufig: 216 - 2400

Kompatibel mit unterschiedlichen Servomotoren

(Siemens, Bosch, etc.)

Hohlwelle

(nur bei zweistufiger Ausführung)

Übersetzung

Zweistufig: 72 - 240 (Hohlwelle möglich)

Dreistufig: 216 - 2400