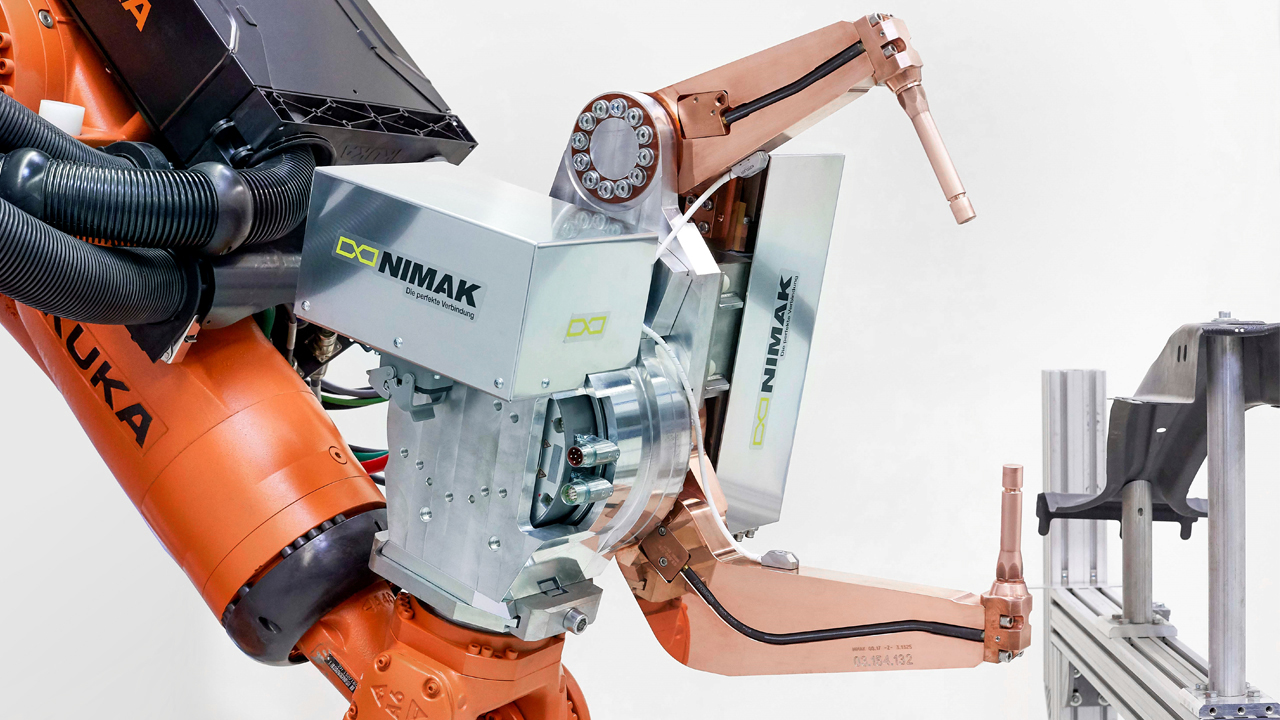

- Extreme rigidity: high precision in medical or industrial robot

- High torque and overload capacity for safety purposes and high system robustness

- Small footprint: flexibility of system

- Easy replacement of existing strain wave or cycloid gearboxes due to output interface compatibility

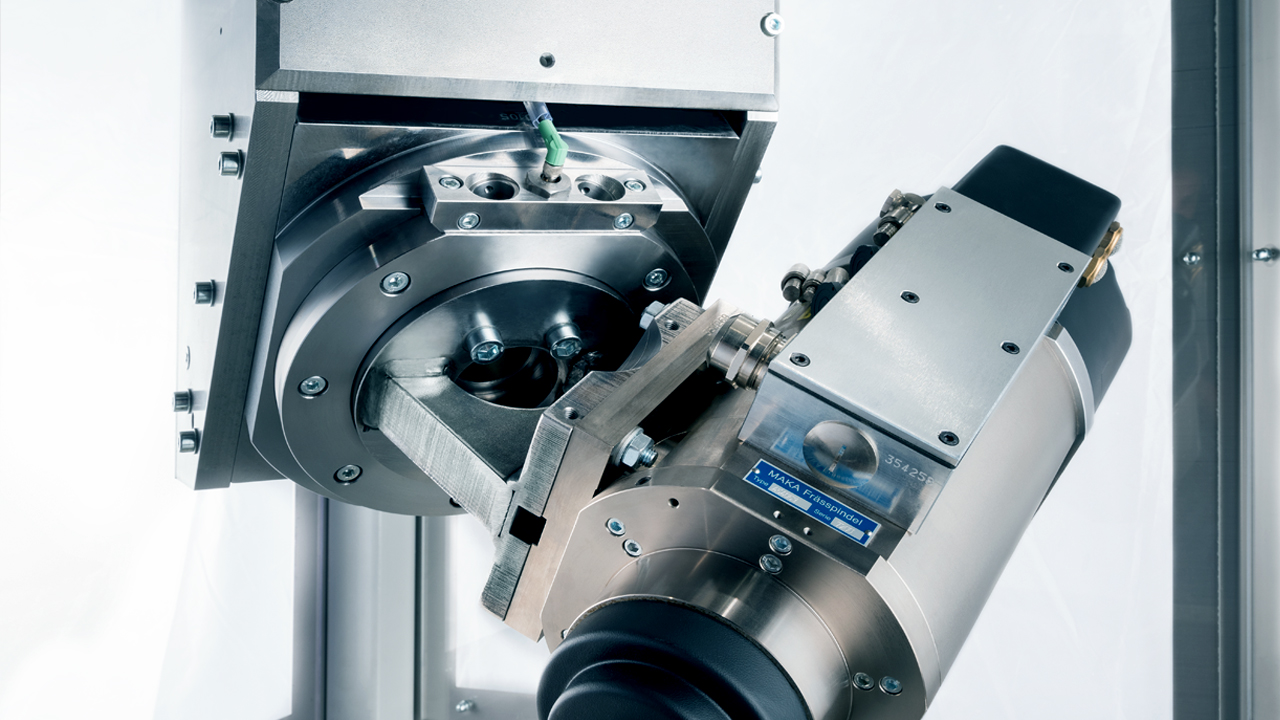

Galaxie® gearbox miniaturized

The most compact hollow-shaft gearbox with the highest torsional rigidity

With the miniaturized Galaxie®, we have taken the functional principle of our classic Galaxie® a step further. The result: innovative kinematics enabling almost full surface contact during power transmission – with an extremely compact footprint. Thanks to this unique concept, the miniaturized Galaxie® performs significantly better than established gearbox types with the same diameter in almost all dimensions. It combines the highest levels of rigidity, torque density and overload capacity with a very large hollow shaft and maintains zero backlash throughout its entire service life.

Downloads

- Flyer (2 MB)

- Data sheet SAG090 (157 KB)

- Data sheet SAG110 (148 KB)

- Technical data (CAD, dimension sheet, data sheet)

Your benefits

More precision due to:

- Extremely high rigidity

- Greater damping

- Higher machining precision

- Absolute zero backlash

Space and weight savings

- Downsizing of drive

- Upgrading of application with unchanged footprint

- Efficient use of hollow shaft

Maximum safety

- Safety reserves in case of overload

- Minimization of downtimes, e.g. due to broken cables in supplied media

Higher productivity

- Faster and more accurate positioning

- Reduced vibrations in system

- Minimized cable breakage

The miniaturized Galaxie® gearbox also forms a perfect motor-gearbox combination in conjunction with the servo motors of the cyber® kit line. As a rule, hollow-shaft motors from other manufacturers can also be integrated.

Large hollow shaft, e.g. for routing cables or for integrating media and/or components

Special tooth design for high gear ratios with almost complete surface contact