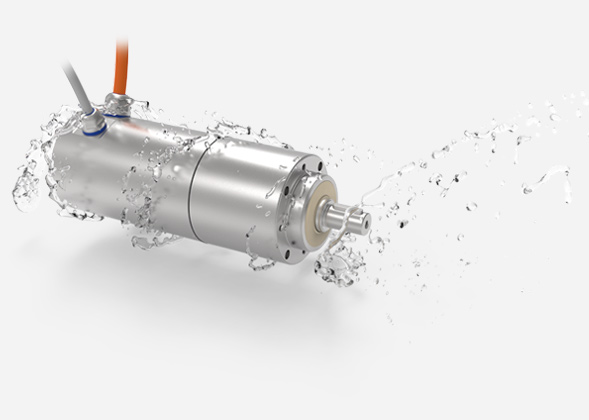

Normally machines must keep critical components in enclosures for protection from corrosion during cleaning processes.

In meat processing applications, daily cleaning is essential to prevent germs and bacteria from building up inside the machines. However, harsh detergents and high-pressure wash-downs can cause seals and bearings of key components to corrode and wear down over time.

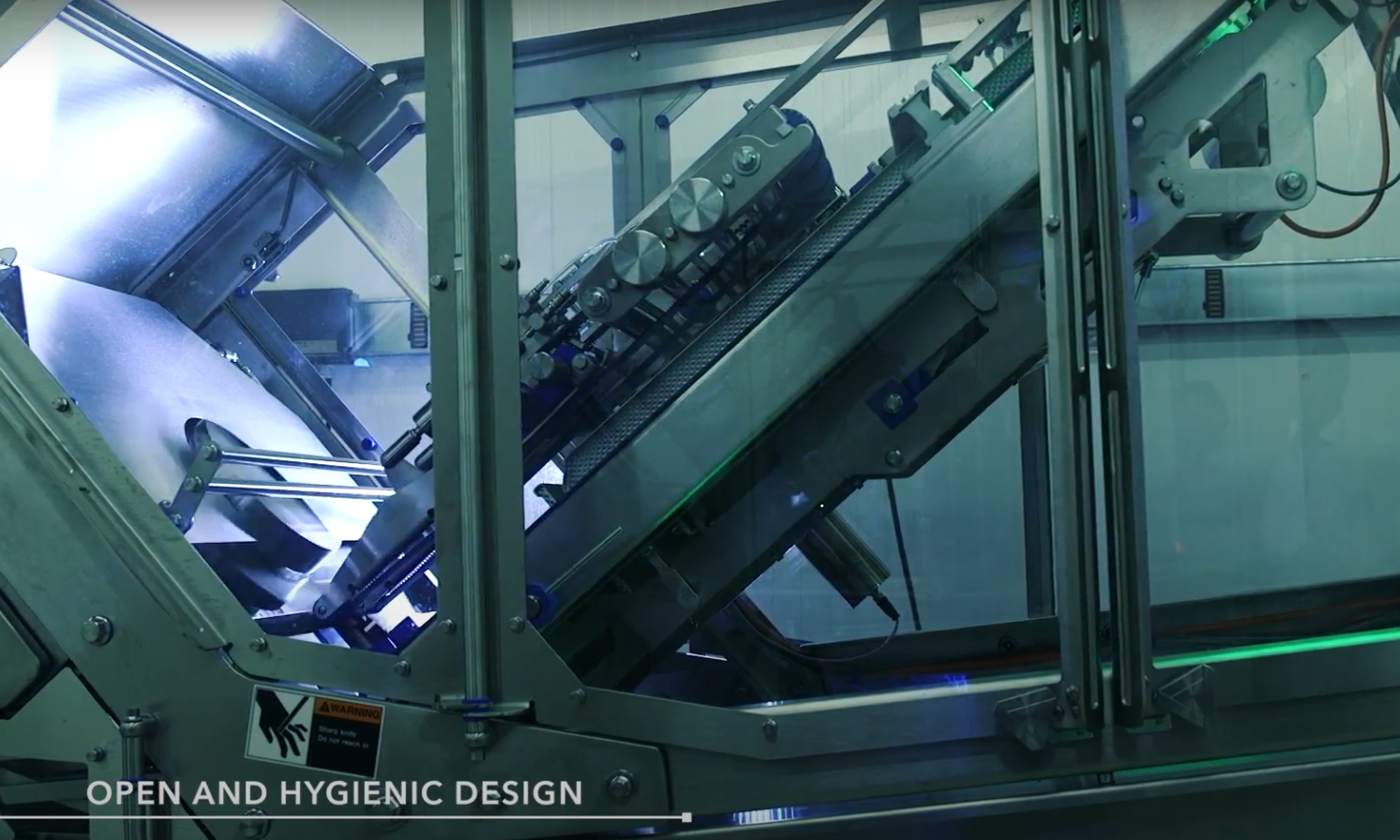

However enclosing these critical components makes cleaning and sanitizing the machine more time consuming and difficult, which can lead to less effective results. Provisur concluded an open architecture design would facilitate improved cleaning, and called on WITTENSTEIN to consult on potential solutions. After closely working with Provisur engineers to confirm performance and design requirements, WITTENSTEIN concluded the axenia actuator was the ideal solution.