Learning about Galaxies' revolutionary performance inspired MGS engineers to think about ways to leverage the zero-backlash precision. After 12 months an opportunity evolved, in the form of a customer request for a highly customized indexing table with high precision for a medical application.

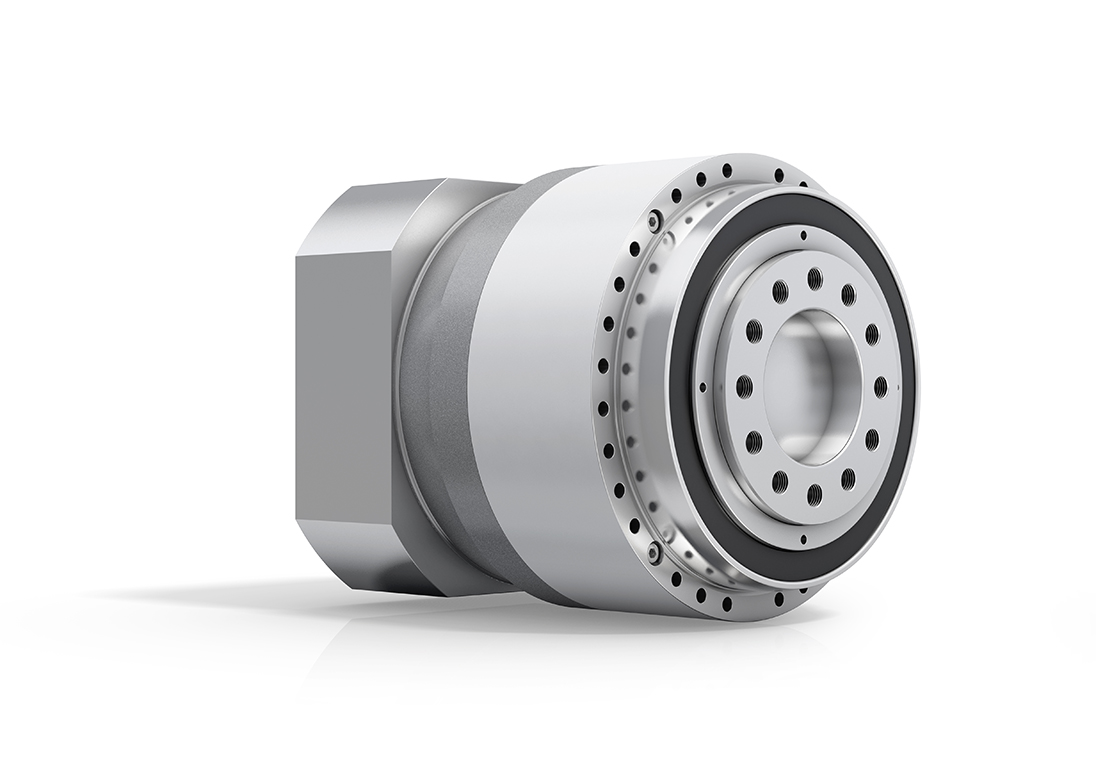

The team concluded torsional rigidity was critical for the axis — if the gear-box is not rigid enough, the table could rotate or oscillate when decelerating to a stop, causing longer move times due to the settling time. Planetary or harmonic design gearboxes simply did not have the required stiffness.