We are driving digitalization forward

The digital transformation is well under way in many branches of industry. To enable us to make the most of the opportunities which Industry 4.0 presents to us and our customers, we set up a new organizational unit in 2016 – the Digitalization Center.

A team of sensor, electronics, software, data and cloud specialists are currently driving digitalization forward there. The team’s playing fields are on the one hand digital services for our customers and on the other the transformation of our internal value added. In both cases, the aim is to increase efficiency. Making WITTENSTEIN employees fit for the digital world is another major focus.

Our vision

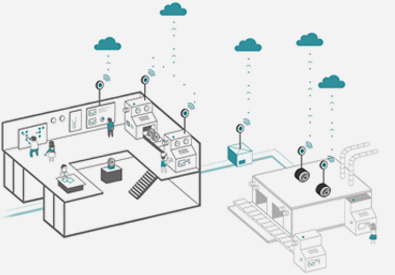

Self-learning products and systems become interconnected through digital awareness.

WITTENSTEIN products know their natural environment and interact independently within it. They communicate, learn, watch and grow with their related products, machines, systems and networks.

Human beings at the center of the factory control the value chain by means of the virtual replica.

The human beings at the center of the factory control the physical value added by means of virtually networked replicas of the value chain formed by suppliers, customers and WITTENSTEIN.

Four agile trains

In order to capitalize on the opportunities of digitalization, the Digitalization Center has defined four strategy fields, referred to as agile trains: Smart Factory, Smart Products & Data Driven Services, Smart Customer Journey and Digital Transformation.

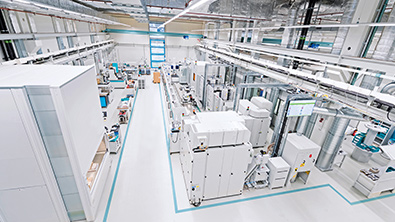

Smart Factory

The central challenge facing industry lies in finding a way to make growing complexity and the increasing trend towards mass customization manageable. This can only happen within a digitally networked manufacturing environment. The Smart Factory train, therefore, addresses an environment in which production machinery and logistics systems are linked to human beings and have the capability to organize themselves. This human centered digitalization focuses on a shared learning process for all employees as a basis for seizing the opportunities of digitalization wisely.

Support for employees on the line

One current project involves the implementation of a CPS (cyber-physical system) to support employees on the line and achieve higher process reliability. This CPS allows order and process-related data on the workpiece to be made available directly at the workplace. A touch screen provides employees with information on necessary materials, process descriptions and additional visual information to simplify assembly (pick-by-light).

Smart Products & Data Driven Services

If information flows must be made more efficient, and simulation options created, during a product’s planning and development phase, we can offer totally new services to our customers in the use phase. This is precisely what the Smart Products & Data Driven Services train is all about. Cloud capabilities and the Internet of Things mean products can be enhanced with smart services and made interoperable through Industry 4.0 standards.

Digital services for our customers

WITTENSTEIN is presently working on both product and non-product related services. In connection with condition monitoring or predictive maintenance, for example, these services deliver more value added to customers, not only during the use phase. A hysteresis service, say, enables variations in the Galaxie® Drive System’s precision to be detected throughout its lifetime as part of process quality assurance.

The focus when developing and providing such services is on as broad a range of applications as possible – whether in manufacturer or customer-specific systems or in IIoT ecosystems like Siemens MindSphere or Adamos. Our smart services are designed to be operable in predefined ecosystems with a minimum of modifications. We also develop smart sensor and service solutions which do not cause any interruption contours on existing products and can be integrated seamlessly into present and future machine generations.

Smart Customer Journey

Im Train Smart Customer Journey entwickeln wir für unsere Kunden Software, die sie beim Finden des passenden Produkts, beim Kauf, bei der Inbetriebnahme, während des laufenden Betriebs und bei der Ablöse unterstützen. Beispiele dafür sind unsere Auslegungstools cymex® 5, SIZING ASSISTANT und CAD POINT sowie unser WITTENSTEIN Service-Portal.

Kundenindividuelle Berührungspunkte entlang des Kundenlebenszyklus

Übergeordnetes Ziel ist es, die neuen digitalen Möglichkeiten für eine exzellente Kundenbindung einzusetzen. Deshalb werden in der sogenannten Smart Customer Journey hochentwickelte, digitale Berührungspunkte künftig den gesamten Kundenlebenszyklus begleiten. Sie sind ein wesentlicher Beitrag, um das Kundenerlebnis an den einzelnen Kontaktpunkten zu optimieren und die bestehende Beziehung zu unterstützen.

Digital Transformation

Ohne den Train Digital Transformation wären unsere übrigen Aktivitäten nicht realisierbar. Um digitaler Innovationsführer zu werden, fördern wir eine agile Unternehmenskultur und erarbeiten uns zukunftsfähige Kompetenzen. Das gibt uns wertvollen Vorsprung – z. B. bei der Umsetzung von Ideen und oder bei der Entwicklung neuer digitaler Geschäftsmodelle.

Bei all unseren Aktivitäten steht der Mensch im Mittelpunkt unseres Denkens: Wir zeigen Mitarbeitern die Chancen der digitalen Transformation auf, bilden sie weiter und bieten ihnen Orientierung im Wandel.

Umfangreiches Networking

Ein weiterer Schwerpunkt des Trains ist die Pflege und der Ausbau von Partnernetzwerken – etwa mit Forschungsinstituten, Verbänden und Hochschulen. Wir kooperieren u. a. mit dem VDMA, ZVEI, der Plattform Industrie 4.0, der Allianz Industrie 4.0 Baden-Württemberg und dem Fraunhofer Institut. Auch Entwicklungspartnerschaften mit unseren Leitkunden betrachten wir als essenziell für den Weg in eine digitale Zukunft.